EQUIPMENT FOR TRANSPORTING SOLAR PANELS

A conveyor line for modules, laminates and glasses to your specifications. With an individual adaptation of the transport technology to your needs, your production line is characterized by error-free transport of your products or materials and guarantees stable and reliable processes.

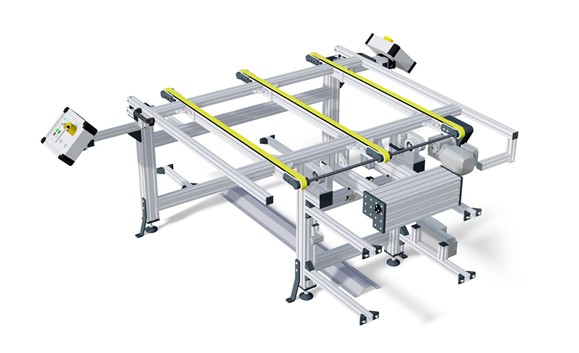

Ball and roller tables

Manual transport of glasses, plates and frames when carried with the mirrors down. The table surface is equipped with ball or roller tracks and can also be equipped with a passage flap if necessary. Some of the bands are adjustable and can therefore be used for different sizes.

Image 1: Ball castor table 2000X2000 with Passageway door

Image 2: Roller table 2000X1600

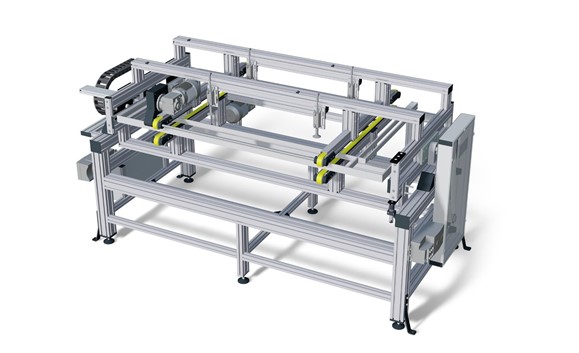

Conveyer belts

Automatic transfer of glasses, plates and frames when transporting with the mirror down. The transport is done by toothed conveyor belts.

Track width, support height, conveying direction and also the number of belts vary per conveyor belt.

Image 1: Belt conveyor LEL double (3 Belts)

Image 2: Belt conveyor SEL single (2 Belts)

Image 3: Belt conveyor LEL single (3 Belts) with passageway door

Transfer stations

Automatic transfer of glasses, plates and frames when transporting with the mirror down. Complete movement on rollers / rolls for feeding / feeding from the line or switching from manual transfer to automatic transfer and vice versa. Button setting.

Image 1: Transfer station belt to ball castor LEL

Image 2: Transfer station belt to roller table LEL

Corner converter

Automatic transfer of units at an angle of 90 ° or separation of units from batches in a row.

Available as double cross conveyor for manual removal or with cross discharge and moving roller conveyors with pneumatic lift.

Image 1: Double-corner conveyor

Turning station 90°

Automatic transfer of glasses, plates and frames when transporting with the mirror down. 90° rotation of modules and later transfer with changed orientation.

It can be built in conjunction with an angular converter as a backend or frontend version.

Image 1: Turning station 90°

Image 2: Corner belt conveyor with bidirectional turning station

Flipper

Manual or automatic rotation of glasses, sheets and frames by 180 ° (on request and frameless units with junction box).

For automatic pinball stations, junction boxes and cables (if present) must be secured to the unit so that they do not catch on the rotating station.

Image 1: Module flip automatic

Image 2: Module flip manual SEL

Image 3: Module flipper

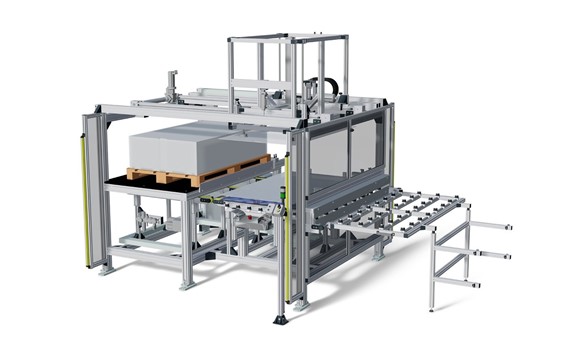

Glass loading

The glasses are placed on the loading table via a forklift. The user should move out of the protected area and start the system. A 2-axis system moves over the pallet (X-axis electrical, Z-axis pneumatic), holding the top tray via vacuum suction cups. The tray is slightly bent to avoid adhesive forces, air is forced between the upper and lower trays through blowing nozzles. The Z axis moves to the upper extreme position and then the X axis moves to the deposit position above the conveyor belt.

Fully or semi-automatic glass loading is available.

Image 1: Glass loading/unloading semi-automatic LEL

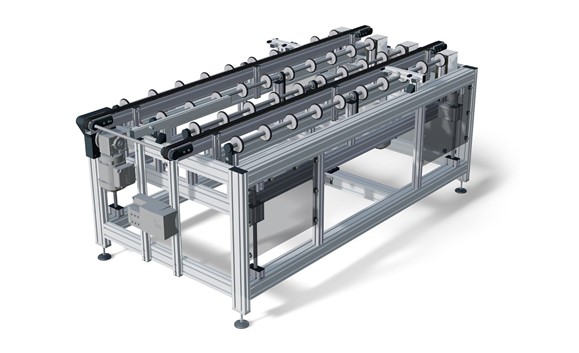

Laminator belts

From 4-lane toothed belt conveyors, to SEL and LEL directional conveying lines, to toothed belt conveyors with integrated angle transport, the choice ranges for sheet transport. The transfer of sheets can be adapted to your needs with individual settings of the dimensions.

Image 1: Laminator conveyor 4-lanes timing belt 32 with ball caster lift

Image 2: Corner converter CTC bidirectional

Image 3: Conveyor line BBC LEL

SOLUTIONS

Our engineers produce ready-to-use solutions for every job in the construction of plants and special machines for you, based on our profile system. From workstation for assembly, transport and protection systems to fully automated integrated solutions. As a full service provider, we are your trusted partner. From design to implementation to training and support.