ADDITIONAL EQUIPMENT

Offline equipment serves as additional material in the unit production line. Whether installed in your production line or as an add-on, offline equipment fulfills its auxiliary role and serves you as a repair station or for transporting various materials.

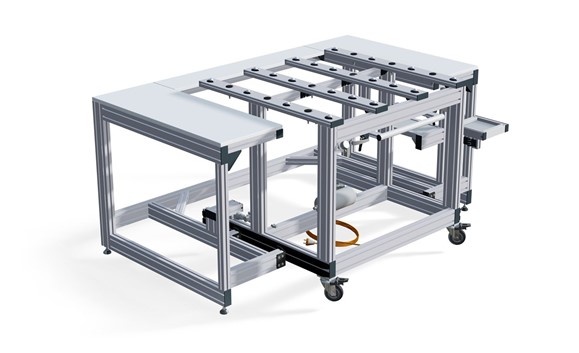

Repair stations

Our repair stations consist of a base frame made of several different aluminum profiles. Individual functions can be achieved with extensive superstructures. This creates various repair stations, for example for modules, laminates or strings.

Image 1: Laminate repair site with a transport cart

Image 2: Module repair workstation low-cost with a transport cart

Trolleys

Suitable for carrying and storing strings, tapes and rolls. Made of various MiniTec profiles.

Image 1: Transport trolley foils

Image 2: Transport trolley string boxes

Adhesive application junction box

The operator fills the loading point with unprepared junction boxes and then starts automatic processing with the button. The preparation station first applies one or two strips of double-sided tape to the container. Once this process is complete, the container should be fitted with a rotating silicone bead. The finished container is then made available to the operator. The operator removes the container, fills the loading point with new containers and starts a new process.

To ensure reliable operation of the preparation station, the levels of the individual consumables are monitored in an appropriate manner.

The layout of the preparation station is visually identifiable with a transparent cover.

Image 1: Tape application connection socket

SOLUTIONS

Our engineers produce ready-to-use solutions for every job in the construction of plants and special machines for you, based on our profile system. From workstation for assembly, transport and protection systems to fully automated integrated solutions. As a full service provider, we are your trusted partner. From design to implementation to training and support.